2 papa Nā Papa Kaapuni Paʻi Paʻi ʻia maʻamau Nā PCB

ʻIke kumu

| Hōʻike No. | PCB-A42 |

| Puke halihali | Hoʻopaʻa ʻumehana |

| Palapala hōʻoia | UL, ISO9001 & ISO14001, RoHS |

| Palapala noi | Mea uila uila |

| Wahi liʻiliʻi/Line | 0.075mm/3mil |

| Kapa Hana Hana | 720,000 M2/makahiki |

| HS Code | 853400900 |

| Ke kumu | Hana ʻia ma Kina |

Hōʻike huahana

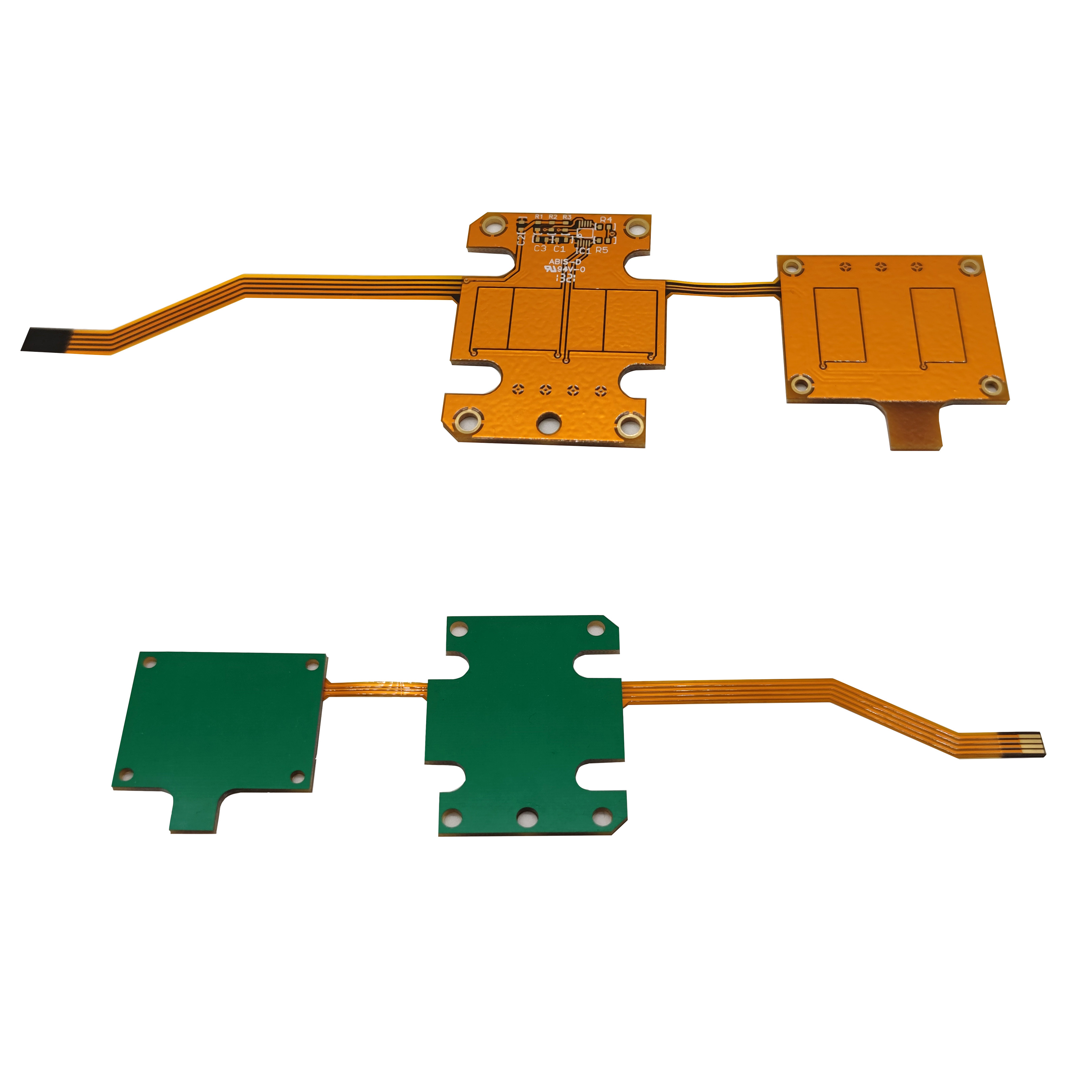

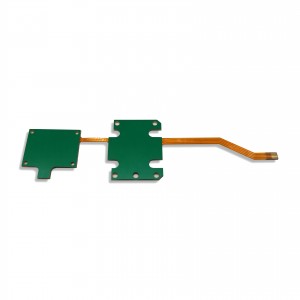

ʻO ka nānā ʻana o ka papa kaapuni paʻi maʻalahi

Wehewehe

PCB hikiwawe - Kaapuni Paʻi Paʻi ʻia, i kapa ʻia ʻo FPC.

Hiki ke wehewehe ʻia kahi kaapuni paʻi maʻalahi ma ke ʻano he outline o nā meheu conductive i hoʻopaʻa ʻia ma kahi substrate maʻalahi.Hana ʻia ʻo ia i mau hiʻohiʻona kaapuni conductor me ka hoʻohana ʻana i ke ʻano māmā e hōʻike i ka hoʻololi ʻana a me nā kaʻina hana etching ma ka ʻili o kahi substrate maʻalahi.

Nā hiʻohiʻona

Hoʻohana nui ʻia ʻo Flex circuits i nā kelepona paʻalima, nā kāmela a me nā akamaihiki ke komo.

Hiki iā ia ke kūpono i ka mana uwea ma nā ākea ma mua o nā papa paʻa kuʻuna. Ua ʻoi aku ka maikaʻi o nā papa kaapuni maʻalahi i nā wela kiʻekiʻe, haʻalulu a haʻalulu.Loaʻa iā ia ka hana maikaʻi me nā hoʻolālā hoʻolālā e like me: nā crossovers hiki ʻole ke pale ʻia, nā koi impedance kikoʻī, ka hoʻopau ʻana i ke kamaʻilio keʻa, ka pale hou a me ka nui o nā mea kiʻekiʻe.

Hoʻokaʻawale

Hoʻokahi ʻaoʻao flex PCB

Hoʻokahi ʻaoʻao flex me ʻeluakomo

PCB hoʻololi ʻelua ʻaoʻao

ʻO ka PCB hoʻololi-nui

ʻenehana & hiki

| 'ikamu | Speci. |

| Nā ʻāpana | 1~8 |

| Mānoanoa Papa | 0.1mm-0.2mm |

| Mea Papahana | PI(0.5mil,1mil,2mil),PET(0.5mil,1mil) |

| Medium Conductive | Peila keleawe(1/3oz,1/2oz,1oz,2oz) Constantana Kāleka Kāleka Inika keleawe |

| Nui Nui o ka Panel | 600mm×1200mm |

| Min Hole Nui | 0.1mm |

| Min Laina Laulā/Lua | 3mil(0.075mm) |

| ʻO ka nui hoʻokau kiʻekiʻe loa (panel hoʻokahi & pālua) | 610mm*1200mm(Ka palena hoʻolaha) 250mm*35mm(hoʻomohala wale i nā laʻana hoʻāʻo) |

| ʻO ka nui hoʻokau kiʻekiʻe (pane hoʻokahi & panel pālua ʻaʻohe PTH inika maloʻo ponoʻī + paʻa kukui UV) | 610*1650mm |

| Luwaha wili (Mechanical) | 17um--175um |

| Hole Hoʻopau (Mechanical) | 0.10mm--6.30mm |

| ʻO ka hoʻomanawanui ʻana (Mechanical) | 0.05mm |

| Kakau inoa (Mechanical) | 0.075mm |

| ʻAspect Ratio | 2:1 (0.1mm ka puka liʻiliʻi) 5:1 (0.2mm ka puka liʻiliʻi) 8:1 (0.3mm ka puka liʻiliʻi) |

| SMT Mini.Laulā Māka Solder | 0.075mm |

| Mini.Hoʻomaʻemaʻe Palekana Solder | 0.05mm |

| Ka hoʻomanawanui impedance | 士10% |

| Hoʻopau ʻili | ENIG, HASL, Kem.Tin/Sn |

| Palekana Solder/Paʻi Kiʻiʻoniʻoni | PI(0.5mil,1mil,2mil)( Melemele, Keʻokeʻo, ʻEleʻele) PET(1mil,2mil) ʻO ka mask solder ('ōmaʻomaʻo, melemele, ʻeleʻele...) |

| Silkscreen | ʻulaʻula/melemele/ʻeleʻele/keʻokeʻo |

| Palapala | UL, ISO 9001, ISO14001, IATF16949 |

| Noi Kuikawa | Pili(3M467,3M468,3M9077,TESA8853...) |

| Mea Hoolako Mea | Shengyi, ITEQ, Taiyo, etc. |

| Pūʻolo maʻamau | Māmā + Kāpena |

| ʻO ka mana hana o kēlā me kēia mahina/m² | 60,000 m² |

Hiki ke alakai manawa PCB

| Puʻupuʻu liʻiliʻiVolume ≤1 mika mika | Nā lā hana | Nuipa? iecaianoaaiiuo | Nā lā hana |

| ʻaoʻao hoʻokahi | 3-4 | ʻaoʻao hoʻokahi | 8-10 |

| 2-4 papa | 4-5 | 2-4 papa | 10-12 |

| 6-8 papa | 10-12 | 6-8 papa | 14-18 |

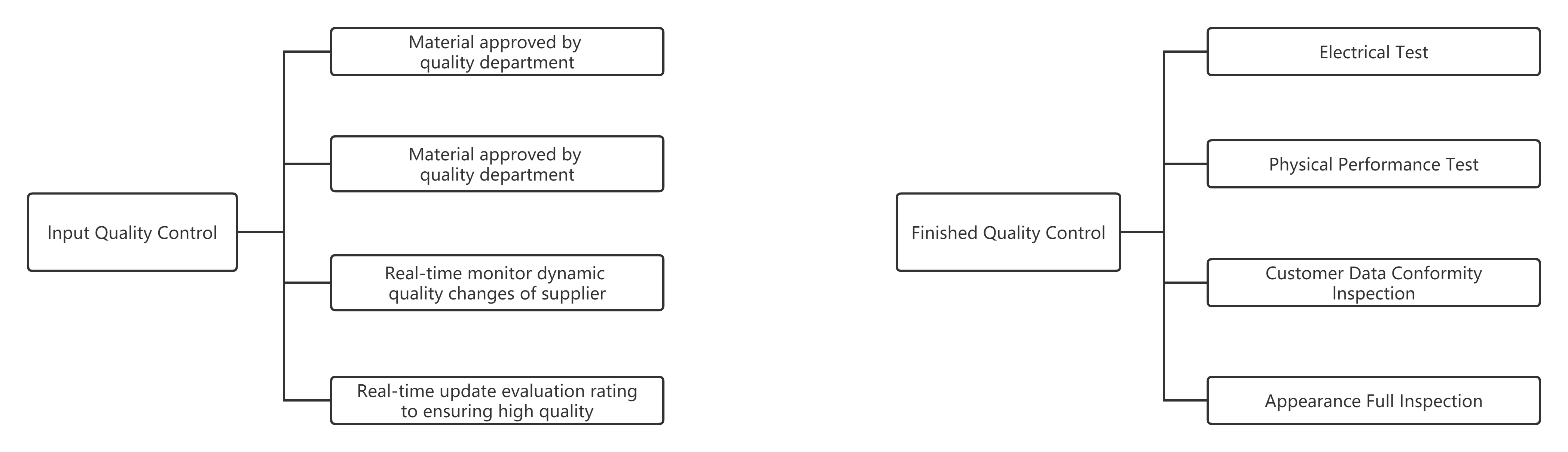

Pehea ka hana ʻana o ABIS me nā pilikia PCB maʻalahi?

ʻO ka mea mua a mākou e hōʻoiaʻiʻo ai ʻo ia ka lako pono e hana i kāu papa.Ma hope aʻe, ua lawa ka ʻike o nā limahana e hoʻoponopono i ka pilikia o ka hana ʻana i nā papa maʻalahi.

ʻO ka wehe ʻana i kahi mask solder a i ʻole ka uhi ʻana i nā ʻanuʻu like ʻole o ke kaʻina hana hiki ke hoʻololi i ke ʻano o ka papa maʻalahi.Hiki i ka etching a me ka plating ke hoʻoponopono i ke ʻano o ka PCB, ʻo ia ke kumu e pono ai ʻoe e hōʻoia i ka laulā kūpono o ka uhi ʻana.

E koho pono i nā mea, e noʻonoʻo ana i nā mea ʻē aʻe, e like me ka nui, ke kaumaha, a me ka hilinaʻi o ka papa.

E hoʻomalu i ka pili kūpono o nā hui solder a me ka piko piko - pono ka hui solder ma kahi i makemake ʻia mai kahi e kulou ai.Inā hoʻokomo ʻoe iā lākou i kahi kokoke loa, hiki mai paha ka delamination a i ʻole ka haki solder pad.

E hoʻomalu i ka spacing Solder pad - ABIS e hōʻoiaʻiʻo ana he lawa ka hakahaka ma waena o nā pads a me nā ala conductive e pili ana iā lākou, i pale aku ai i ka nalowale o ka lamination.

Misiona Pono ABIS

ʻO ka helu o nā mea e hiki mai ana ma luna o 99.9%, ʻo ka helu o ka nui o ka hōʻole ʻana ma lalo o 0.01%.

Mālama nā ʻoihana i hōʻoia ʻia e ABIS i nā kaʻina hana nui e hoʻopau i nā pilikia āpau ma mua o ka hana ʻana.

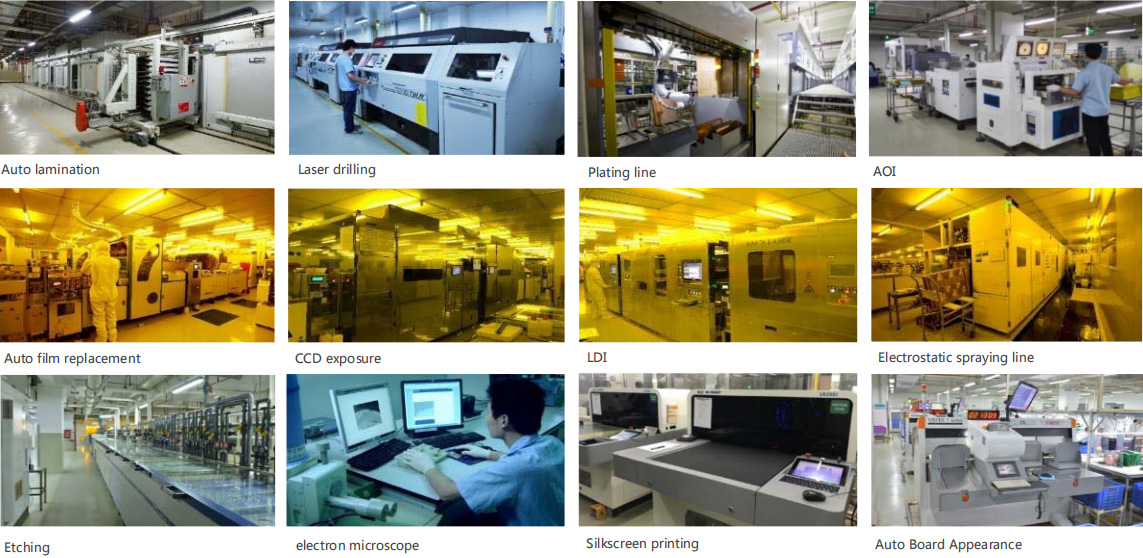

Hoʻohana ʻo ABIS i nā polokalamu holomua e hana i ka loiloi DFM nui ma nā ʻikepili e hiki mai ana, a hoʻohana i nā ʻōnaehana hoʻokele maikaʻi i ka wā o ke kaʻina hana.

Hana ʻo ABIS i ka 100% nānā ʻike a me AOI a me ka hoʻokō ʻana i ka hoʻāʻo uila, ka hoʻāʻo uila kiʻekiʻe, ka hoʻāʻo impedance control, micro-sectioning, thermal shock testing, solder testing, reliability testing, insulating resistance testing and ionic cleanliness testing.

Palapala

FAQ

E loaʻa i kēlā me kēia mea kūʻai ke kūʻai aku iā ʻoe.Ko makou hola hana: AM 9:00-PM 19:00(Beijing Time) mai Poakahi a Poalima.E pane koke mākou i kāu leka uila i ko mākou manawa hana.A hiki iā ʻoe ke hoʻokaʻaʻike i kā mākou kūʻai aku ma ke kelepona inā wikiwiki.

ʻO kā mākou mau kaʻina hana hōʻoia maikaʻi e like me lalo:

a), Nānā Kiʻi

b), ʻImi lele, mea paahana

c), Ka hoʻomalu impedance

d), ʻIke hiki ke kūʻai

e), ʻenekini ʻeleʻele metallograghic

f), AOI (Nānā Optical Aunoa)

ʻO ka maʻamau 2-3 mau lā no ka hana laʻana.ʻO ka manawa alakaʻi o ka hana nui e hilinaʻi i ka nui o ke kauoha a me ke kau āu e kau ai i ke kauoha.

ʻO kā mākou mau kaʻina hana hōʻoia maikaʻi e like me lalo:

a), Nānā Kiʻi

b), ʻImi lele, mea paahana

c), Ka hoʻomalu impedance

d), ʻIke hiki ke kūʻai

e), ʻenekini ʻeleʻele metallograghic

f), AOI (Nānā Optical Aunoa)

ʻAʻohe koi MOQ no ABIS no PCB a i ʻole PCBA.

Hana ʻo ABlS i ka 100% nānā ʻike a me AOl e like me ka hana ʻana i ka hoʻāʻo uila, hoʻāʻo uila kiʻekiʻe,mana impedanceka ho'āʻo, ka micro-sectioning, ka hoʻāʻo ʻana i ka haʻalulu wela, ka hoʻāʻo solder, ka hoʻāʻo ʻana i ka hilinaʻi, ka hoʻāʻo ʻana i ke kūpaʻa insulating, hoʻomaʻemaʻe ionica me ka hoʻāʻo ʻana o ka PCBA.

Eʻoluʻolu e hoʻouna i nā nīnau kiko'ī iā mākou, e like me ka helu helu, ka nui no kēlā me kēia mea, noi maikaʻi, logo, nā hua'ōlelo uku, ke ala lawe, kahi hoʻokuʻu, a me nā mea'ē aʻe.

ʻOi aku ka nui o ka hāʻawi manawa ma mua o 95%

a), 24 hola huli wikiwiki no ka ʻaoʻao ʻelua prototype PCB

b), 48 hola no 4-8 papa prototype PCB

c), 1 hola no ka ʻōlelo ʻana

d), 2 hola no ka nīnau ʻenekinia/manaʻo hoʻopiʻi

e), 7-24 mau hola no ke kākoʻo ʻenehana / lawelawe kauoha / hana hana

| Iecaianoaaiiuo hiki o wela-kūʻai huahana | |

| ʻO ʻaoʻao ʻelua/Multilayer PCB Workshop | Hale Hana PCB Aluminum |

| Hiki i ka ʻenehana | Hiki i ka ʻenehana |

| Nā mea waiwai: CEM-1, CEM-3, FR-4(TG kiʻekiʻe), Rogers, TELFON | Nā mea waiwai: Ke kumu alumini, Ke kumu keleawe |

| Layer: 1 papa i 20 Layer | Layer: 1 papa a me 2 Layer |

| Min.line laula: 3mil/3mil(0.075mm/0.075mm) | Min.laina laula/wahi: 4mil/4mil(0.1mm/0.1mm) |

| Min.Hole nui: 0.1mm (dirilling puka) | Min.Ka nui o ka puka: 12mil(0.3mm) |

| Max.Nui papa: 1200mm* 600mm | Nui ka nui o ka papa: 1200mm* 560mm(47in* 22in) |

| Ka mānoanoa o ka papa i pau: 0.2mm- 6.0mm | Pau ka mānoanoa o ka papa: 0.3 ~ 5mm |

| Ka mānoanoa o ke keleawe: 18um~280um(0.5oz~8oz) | Ka mānoanoa o ke keleawe: 35um~210um(1oz~6oz) |

| NPTH Hole Hoʻomanawanui: +/-0.075mm, PTH hole hoʻomanawanui: +/-0.05mm | Ka hoʻomanawanui kūlana puka: +/-0.05mm |

| Hoʻomanawanui Outline: +/-0.13mm | Ka hoʻomanawanui outline outline: +/ 0.15mm;ke kuʻi ʻana i ka hoʻomanawanui: +/ 0.1mm |

| Hoʻopau ʻia ka ʻili: HASL me ke alakaʻi ʻole, ke gula kaiapuni (ENIG), ke kala kaiapuni, OSP, ka uhi gula, manamana gula, Carbon INK. | Hoʻopau ʻia ka ʻili: ke alakaʻi manuahi HASL, ke gula immersion (ENIG), ke kālā immersion, OSP etc |

| Ka hoʻomanawanui ʻana o ka Impedance: +/-10% | Noho ka mānoanoa hoʻomanawanui: +/-0.1mm |

| Hiki ke hana: 50,000 sqm / mahina | MC PCB Hiki i ka hana: 10,000 sqm / mahina |