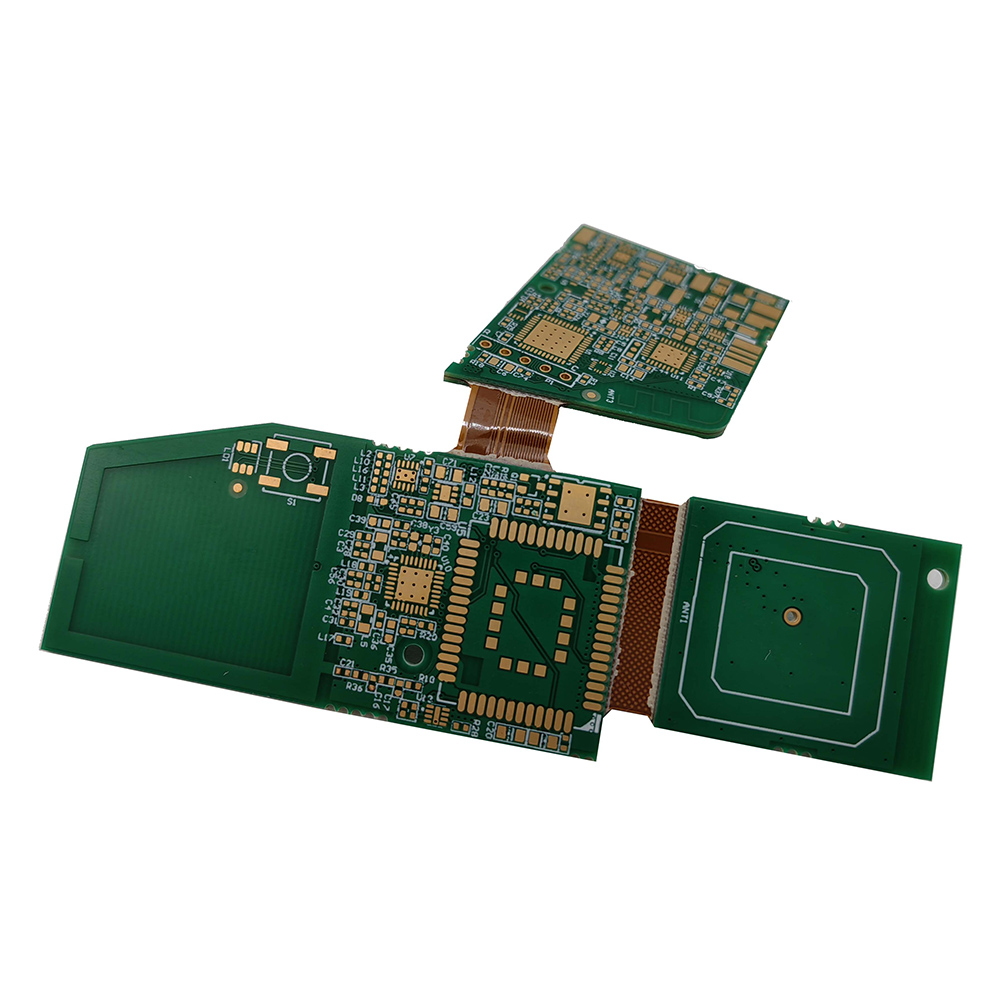

ʻO ABIS Rigid-Flex PCB Papa kaapuni maʻamau i hana ʻia me FR4 a me PI

ʻIke kumu

| Hōʻike No. | PCB-A5 |

| Puke halihali | Hoʻopaʻa ʻumehana |

| Palapala hōʻoia | UL, ISO9001 & ISO14001, RoHS |

| Wehewehe | IPC Papa2 |

| Wahi liʻiliʻi/Line | 0.075mm/3mil |

| Ka hoʻomalu impedance | 50±10% |

| Kapa Hana Hana | 720,000 M2/makahiki |

| Ke kumu | Hana ʻia ma Kina |

Hōʻike huahana

ʻO ka nānā ʻana i nā papa kaapuni paʻi paʻi paʻa

ʻO ka manaʻo maoli o "rigid-flex" ka hui pū ʻana i nā pono o nā papa maʻalahi a paʻa.ʻIke ʻia ʻo ia ʻelua-ma-hoʻokahi kaapuni i hoʻopili ʻia ma o nā lua i uhi ʻia.Hiki i nā kaʻapuni flexi ʻoi aku ke kiʻekiʻe o ka ʻāpana ʻoiai e kūpono ana i nā wahi liʻiliʻi a ʻano ʻano ʻē.

ʻO nā papa kaapuni paʻi paʻa ʻoʻoleʻa he nui nā ʻāpana o loko i hoʻopili ʻia me ka hoʻohana ʻana i kahi kiʻiʻoniʻoni hoʻopaʻa epoxy pre-preg, e like me kahi kaapuni hikiwawe multilayer.Ua hoʻohana ʻia nā kaapuni ʻo Rigid flex i ka pūʻali koa a me nā ʻoihana aerospace ma mua o 20 mau makahiki.I ka nui o na papa kaapuni kaapuni paakiki.

ʻenehana & hiki

| 'ikamu | Spec. |

| Nā ʻāpana | 1~8 |

| Mānoanoa Papa | 0.1mm-8.0mm |

| Mea waiwai | Polymide, PET, PEN, FR4

|

| Nui Nui o ka Panel | 600mm×1200mm |

| Min Hole Nui | 0.1mm |

| Min Laina Laulā/Lua | 3mil(0.075mm) |

| Papa Outline tolerance | 士0.10mm |

| Mānoanoa Layer Insulation | 0.075mm--5.00mm |

| Mānoanoa Hope | 0.0024''-0.16'' (0.06-2.4.00mm) |

| Luwaha wili (Mechanical) | 17um--175um |

| Hole Hoʻopau (Mechanical) | 0.10mm--6.30mm |

| ʻO ka hoʻomanawanui ʻana (Mechanical) | 0.05mm |

| Kakau inoa (Mechanical) | 0.075mm |

| ʻAspect Ratio | 16:1 |

| ʻAno Māka Solder | LPI |

| SMT Mini.Laulā Māka Solder | 0.075mm |

| Mini.Hoʻomaʻemaʻe Palekana Solder | 0.05mm |

| Anawaena Puka Puka | 0.25mm--0.60mm |

| Ka hoʻomanawanui impedance | 士10% |

| Hoʻopau ʻili | ENIG, Kem.Tin/Sn, gula Flash |

| Māka solder | ʻOmaomao/melemele/ʻeleʻele/keʻokeʻo/ʻulaʻula/uliuli |

| Silkscreen | ʻulaʻula/melemele/ʻeleʻele/keʻokeʻo |

| Palapala | UL, ISO 9001, ISO14001, IATF16949 |

| Noi Kuikawa | Puka makapō, manamana gula, BGA, ʻīnika kalapona, pale maka nānā, kaʻina VIP, ka uhi ʻaoʻao, ʻAlua lua |

| Mea Hoolako Mea | Shengyi, ITEQ, Taiyo, etc. |

| Pūʻolo maʻamau | Māmā + Kāpena |

Pehea ka lawelawe ʻana o ABIS i ka Kaapuni Flex-Rigid?

ʻO ka hiki ke hoʻohālikelike i ka hui hope o nā PCB paʻa a maʻalahi e hoʻopili i kahi paʻa huahana ʻo ia ka pono mua o nā papa kaapuni maʻalahi.Eia nā ʻōlelo aʻoaʻo 2 e hoʻokomo i kāu papahana hoʻolālā rigid-flex:

E hoʻonui i ka hilinaʻi o ka trace: ʻO ka piʻi ʻana o nā kaapuni paʻa, ʻoi aku ka maikaʻi o ka delaminate o ke keleawe ma mua o ka papa paʻa.ʻOi aku ka liʻiliʻi o ka hoʻohui keleawe i ka substrate ma mua o kahi FR4 PCB pū kekahi.

E hoʻoikaika i nā traces a me nā vias me nā waimaka: Inā ʻaʻole i hoʻomalu ʻia, ʻo ke kulou ʻana i ka substrate hiki ke alakaʻi i ka delamination a me ka pau ʻole o ka huahana.Hiki ke hoʻoikaika ʻia nā traces a me nā vias i mea e pale ai i ka delamination, e hoʻohua maikaʻi hoʻi i ka hana ʻana ma o ka hāʻawi ʻana i ka hoʻomanawanui wili.

Hiki ke alakai manawa PCB

| Puʻupuʻu liʻiliʻiVolume ≤1 mika mika | Nā lā hana | Nuipa? iecaianoaaiiuo | Nā lā hana |

| ʻaoʻao hoʻokahi | 3-4 | ʻaoʻao hoʻokahi | 8-10 |

| 2-4 papa | 4-5 | 2-4 papa | 10-12 |

| 6-8 papa | 10-12 | 6-8 papa | 14-18 |

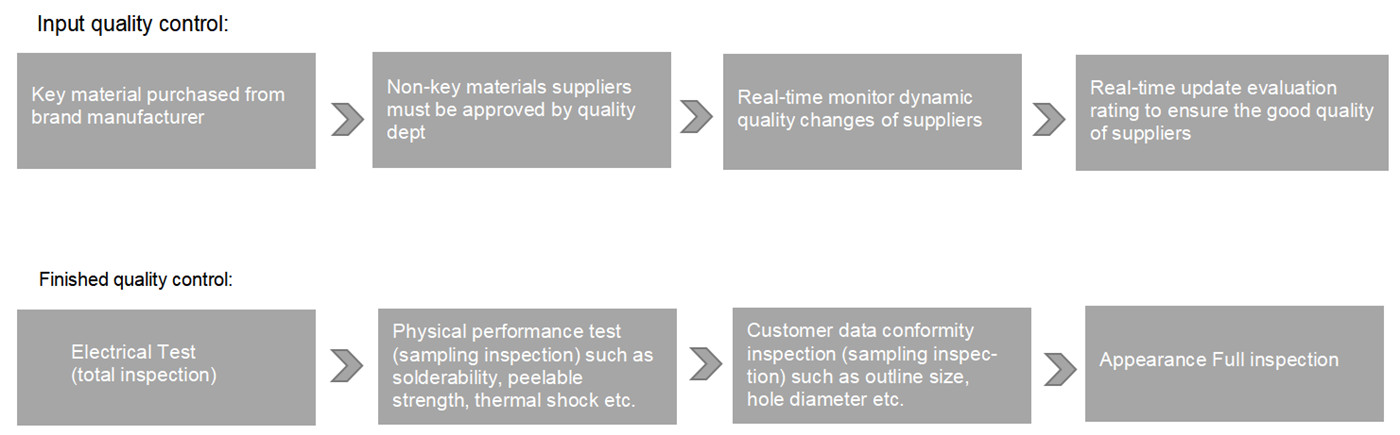

Misiona Pono ABIS

ʻO ka helu hala o nā mea komo ma luna o 99.9%.ʻO ka helu o nā helu hōʻole nui ma lalo o 0.01%.

Hoʻokahi makahiki palapala hoʻokō.inā loaʻa nā pilikia maikaʻi, ʻaʻole ma muli o ka hoʻohana pono ʻole a i hana ʻia e ke kanaka, e hoʻololi ʻo ABIS i kēlā me kēia.

Mālama nā ʻoihana i hōʻoia ʻia e ABIS i nā kaʻina hana nui e hoʻopau i nā pilikia āpau ma mua o ka hana ʻana.

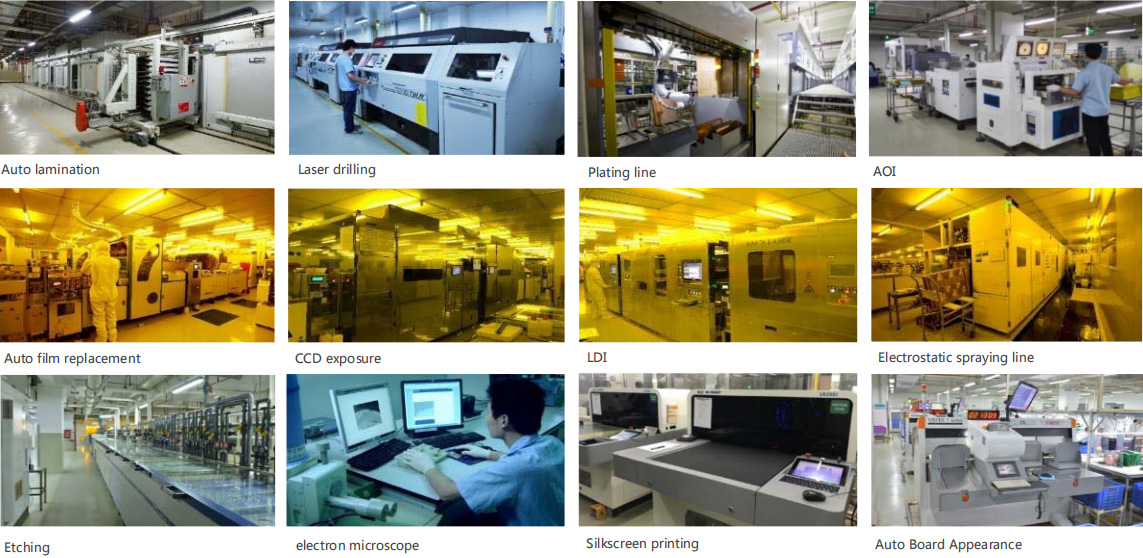

Hoʻohana ʻo ABIS i nā polokalamu holomua e hana i ka loiloi DFM nui ma nā ʻikepili e hiki mai ana, a hoʻohana i nā ʻōnaehana hoʻokele maikaʻi i ka wā o ke kaʻina hana.

Hana ʻo ABIS i ka 100% nānā ʻike a me AOI a me ka hoʻokō ʻana i ka hoʻāʻo uila, High Voltage testing, impedance control testing, micro-sectioning, thermal shock testing, solder testing, reliability testing, insulating resistance testing and ionic cleanliness testing.

Palapala

FAQ

E loaʻa i kēlā me kēia mea kūʻai ke kūʻai aku iā ʻoe.Ko makou hola hana: AM 9:00-PM 19:00(Beijing Time) mai Poakahi a Poalima.E pane koke mākou i kāu leka uila i ko mākou manawa hana.A hiki iā ʻoe ke hoʻokaʻaʻike i kā mākou kūʻai aku ma ke kelepona inā wikiwiki.

Mea Hoʻolako Nui (FR4): Kingboard (Hong Kong), NanYa (Taiwan), a me Shengyi (Kina), Inā ʻē aʻe, e ʻoluʻolu iā RFQ.

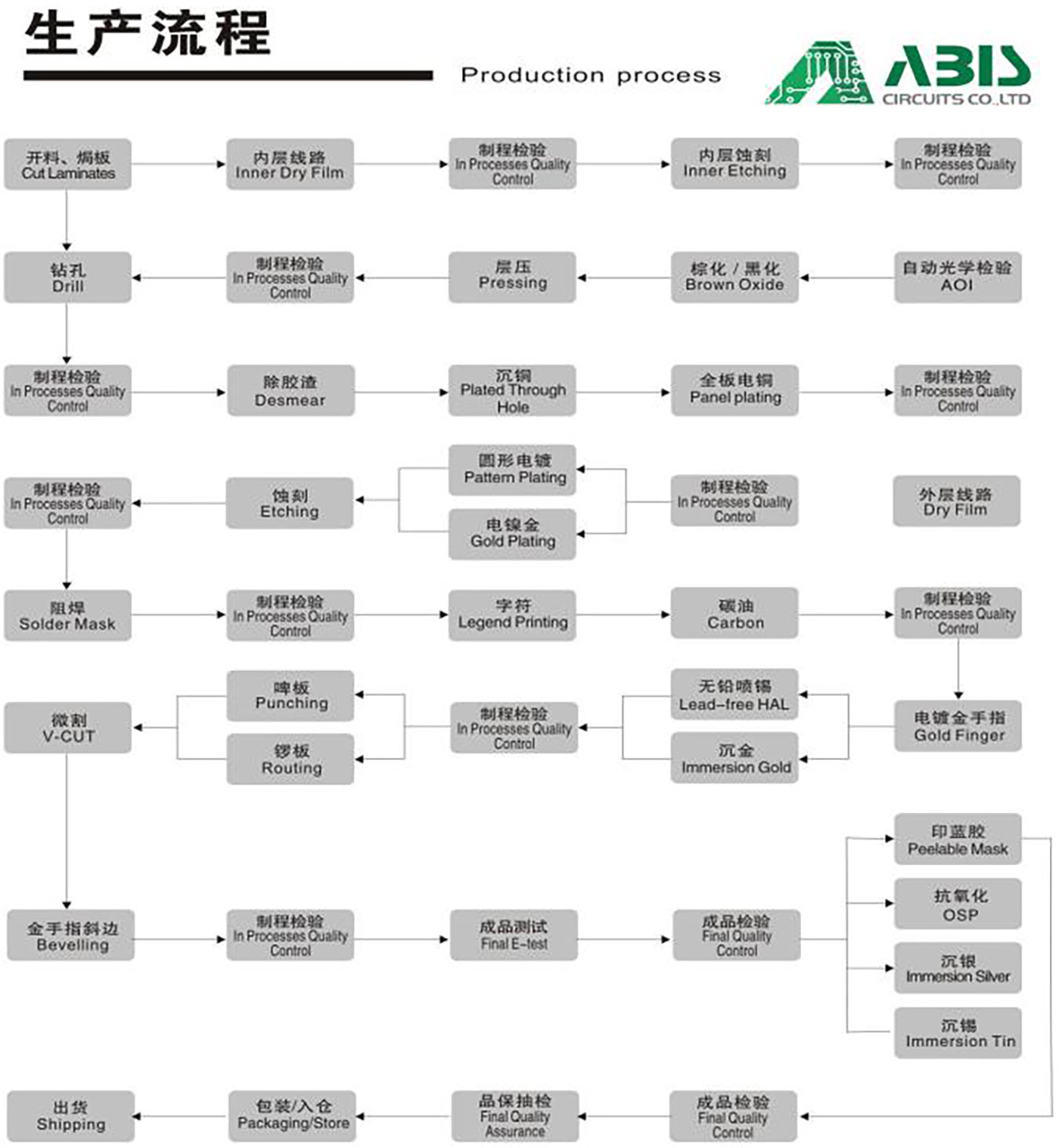

ʻO kā mākou mau kaʻina hana hōʻoia maikaʻi e like me lalo:

a), Nānā Kiʻi

b), ʻImi lele, mea paahana

c), Ka hoʻomalu impedance

d), ʻIke hiki ke kūʻai

e), ʻenekini ʻeleʻele metallograghic

f), AOI (Nānā Optical Aunoa)

ʻO ka maʻamau 2-3 mau lā no ka hana laʻana.ʻO ka manawa alakaʻi o ka hana nui e hilinaʻi i ka nui o ke kauoha a me ke kau āu e kau ai i ke kauoha.

ʻO kā mākou mau kaʻina hana hōʻoia maikaʻi e like me lalo:

a), Nānā Kiʻi

b), ʻImi lele, mea paahana

c), Ka hoʻomalu impedance

d), ʻIke hiki ke kūʻai

e), ʻenekini ʻeleʻele metallograghic

f), AOI (Nānā Optical Aunoa)

ISO9001, ISO14001, UL USA & USA Kanada, IFA16949, SGS, RoHS hōʻike.

Hana ʻo ABlS i ka 100% nānā ʻike a me AOl e like me ka hoʻāʻo ʻana i ka uila, ka hoʻāʻo uila kiʻekiʻe, ka hoʻāʻo ʻana i ka impedance control, micro-sectioning, thermal shock testing, solder testing, reliability testing, insulating resistance testing, ionic cleanliness testing and PCBA Functional testing.

Eʻoluʻolu e hoʻouna i nā nīnau kiko'ī iā mākou, e like me ka helu helu, ka nui no kēlā me kēia mea, noi maikaʻi, logo, nā hua'ōlelo uku, ke ala lawe, kahi hoʻokuʻu, a me nā mea'ē aʻe.

ʻOi aku ka nui o ka hāʻawi manawa ma mua o 95%

a), 24 hola huli wikiwiki no ka ʻaoʻao ʻelua prototype PCB

b), 48 hola no 4-8 papa prototype PCB

c), 1 hola no ka ʻōlelo ʻana

d), 2 hola no ka nīnau ʻenekinia/manaʻo hoʻopiʻi

e), 7-24 mau hola no ke kākoʻo ʻenehana / lawelawe kauoha / hana hana